Ball lollipop production line

Efficient Production

Stable Quality

Variety of Flavors

Labor Saving

Flexible Customization

Durable Equipment

- Commodity name: Ball lollipop production line

- Description

-

The lollipop production line is consisted by the electric sugar cooker, batch roller , rope sizer, center filling machine, lollipop forming machine,cooling shift, packing machine and so on, can produce monochrome, two-color, multicoloured lollipop. Electrical integration control of the whole production line, easy to control the operation, large output, high efficiency, no waste of sugar, is the ideal equipment to produce the greatly lollipop candy.

1)HTL-200 Electrical sugar cooking pot

Characteristics

The machine use electric heating. It has the characteristics of big heating area, high heating efficiency, heat well-distributed, short heating time and the temperature is easily to be controlled. The materials are stirred by scraping the bottom and sides of the pot, no stick on the pot, no stirring dead angle and the stirring is homogeneous. The outside and inside of the pot are formed of one body. It is made of standard SUS 304, accord with food standard health requirements and safe accessories are enough. The machine appearance is beautiful. It is easy to install and operate, safe and reliable.

2)Water Cycle Cooling Table

Application

Using water for cooling

Dimension

2000×1200×800 mm

3)Heat preservation Batch roller

Dimension

2200×700×1400 mm

Voltage

380 V

Power

3 KW

Weight

500 kg

4)Heat preservation Rope sizer

Dimension

2200×700×1400 mm

Voltage

380 V

Power

3 KW

Weight

500 kg

5)HTL-400 Ball Lollipop Candy Forming Machine

Dimension

1115*900*1080 mm

Voltage

380 V

Power

2.2 KW

Weight

580 kg

Output

2-5T/8h

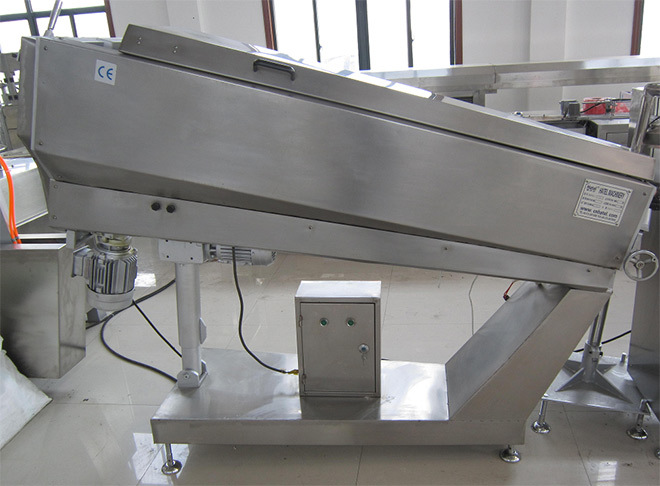

6)Hoister

Machine

Hoister

Voltage

380V/50Hz

Power

0.37 KW

Dimension

1900×700×1750 mm

Weight

150 kg

7)Cooling cabinet

Machine

Cooling cabinet

Voltage

380V/50Hz

Power

3.19 KW

Dimension

3000×1200×2000 mm

Weight

400 kg

8)HTL-200 Lollipop twist wrapping machine

Characteristics

Color-mark adjustable tracking system, computer program and controlled precise positioning, coordination in film supplying, wrapping and strong sealing.

Photoelectric tracking system, self-stop for no product feeding, no empty bags, good self adjustment ability.

Gradual motor to control film feeding seed with product feeding.

Imported frequency transformer, PLC, circumvention coder and light-electrical switch.

Friendly designed, easy for operation and maintenance.

Main technical

Model

HTL-200

Lollipop candy size

Min:φ22; Max;φ30

Film size

Max size:125*125mm

Output(by lollipop candy size φ25mm)

2000kg/8h

Total power

2.2kw

Dimension(L*W*H)

2500*900*1500mm

Total weight

1200kg

Details

Key words:

Related Products